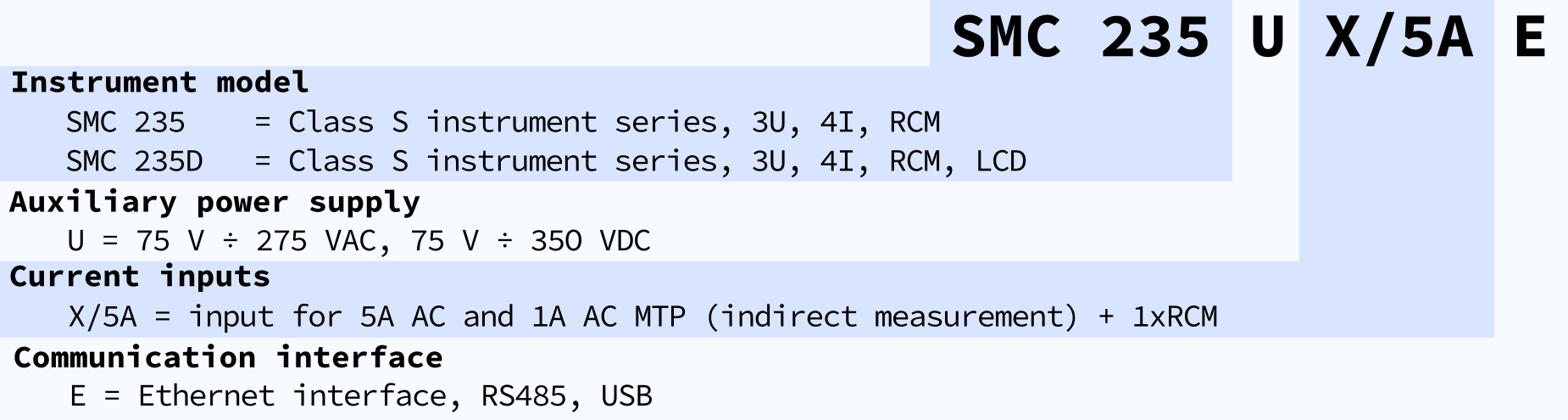

Mid-range class S PQ analyzer and data logger, 0.5S sub-meter, residual current monitoring (RCM), color graphic display option, DIN rail mounted, 6 modules

The SMC 235 is specially designed for monitoring of energy and the related power quality in industrial power systems. This high-end instrument with multiple communication options is suitable for a wide spectrum of automation tasks in modern buildings, distributed power generation, remote supervision of the infrastructure, and also to monitor remote load management. With a proper firmware module, it can be used to collect data from simpler slave units and to provide them up.

The absence of local panel controls (LED panel option without screen and keyboard) limits possibilities for hostile user interaction. Inputs and outputs can be programmed for a wide range of functions and conditions for advanced control applications. In this second generation, the analyzer offers advanced metering and data processing functions for a quick overview and detailed scope capabilities.

It can optionally monitor power quality (with PQ-S module, transients (with GO module) and the ripple control signals (RCS module).

Optional relay or SSR outputs can be programmed to control other equipment based on measured values (useful for fan control, over-voltage/over-current, PQ relaying, etc). Impulse outputs can also forward metered values as an S0 output. The USB port provides quick, easy, and reliable means for configuration and data acquisition. Optional serial or Ethernet interface (with a web server, Modbus TCP, SNTP, DNS, SNMP, DHCP...) allows it to be remotely managed via the ENVIS application. The firmware module is also available with support for the IEC-104 substation automation protocol. In combination with ENVIS.Online service, e_get tools, or embedded library (.NET core, C/C++ for Windows/Linux) its actual values can be also periodically downloaded and stored to a file or remote SQL database for further processing and analysis.

Key features

- three measuring voltage inputs

- four current inputs for 5A or 1A secondary CTs

- special input for precise residual current monitoring

- digital inputs / outputs

- sampling rate of 28 kHz, up to 128 harmonics measured with high accuracy

- measurement and recording of slow transients

- precise four quadrant active and reactive energy measurement

- optional Modbus master archive recording data from connected Modbus RTU slaves

- Extended set of conditions and control actions in the IO programming section

- 512MB internal memory for periodical recording, automatic meter readings, power quality datasets etc.

- aggregation interval from 40 milliseconds to 2 hours

- measurement of harmonic phasors (amplitude, phase)

- advanced time synchronization options: NMEA, PPS, PPM, ...

- optional firmware modules - power quality, Modbus master, ripple-control signal, ethernet-serial, supra-harmonics and transient recorder(oscillograms)

- local USB, remote RS 485 and fast Ethernet communication